| Author |

Message |

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Mon Oct 17, 2016 11:23 pm Posted:

Mon Oct 17, 2016 11:23 pm |

|

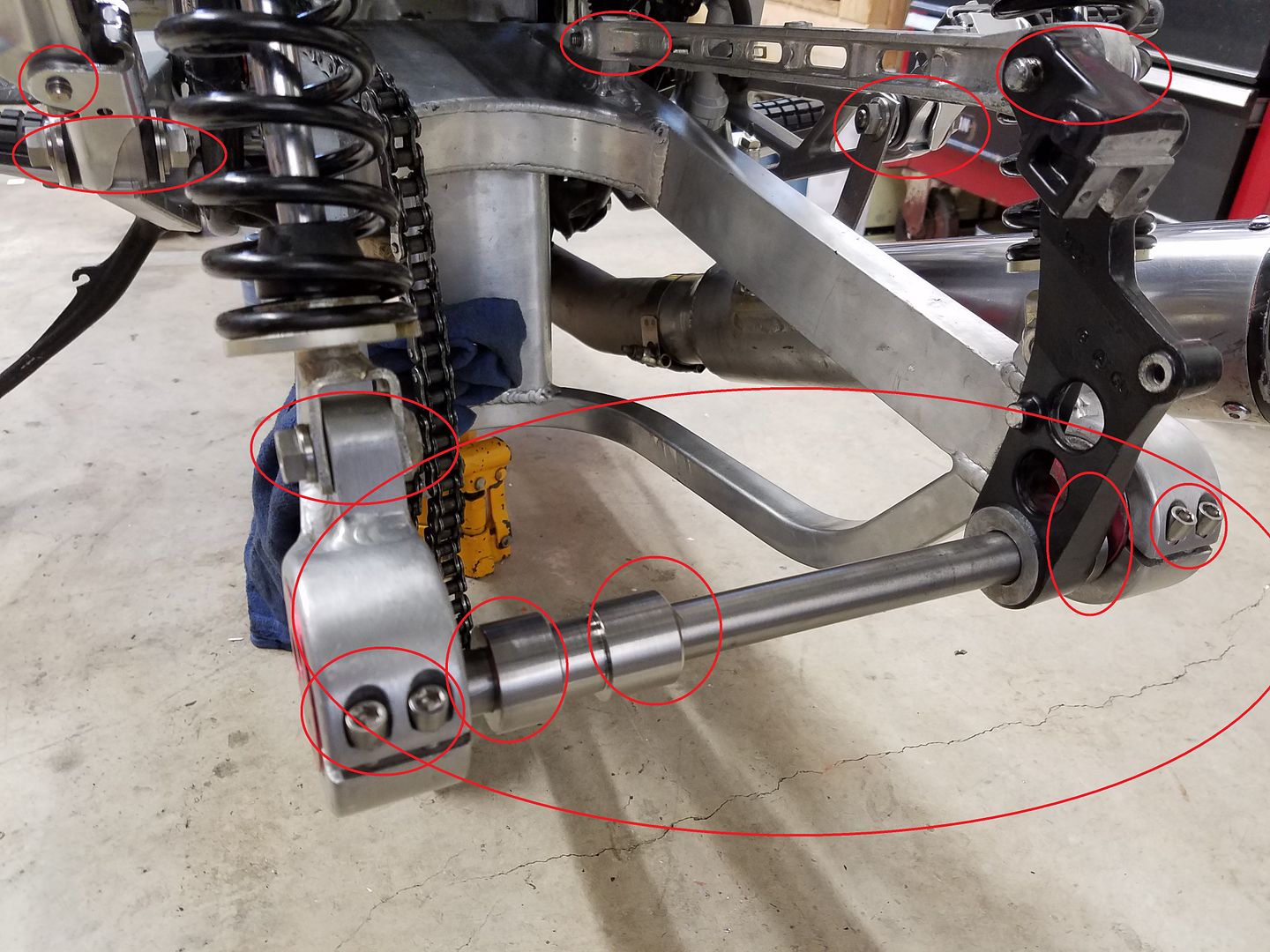

It all started with making a titanium axle.

And I keep adding more and more.

|

_________________

Cary

Last edited by headless on Wed Oct 19, 2016 7:06 pm; edited 1 time in total |

|

|

|

SEBSPEED

Silver CB900F

Joined: Oct 28, 2003

Posts: 1105

Location: Catskill Mtns, New York

|

Posted:

Tue Oct 18, 2016 12:19 am Posted:

Tue Oct 18, 2016 12:19 am |

|

I'm fairly convinced the stock wheels and rotors are cast from lead. Why not trash those in favor of lighter items instead?

Both of my CBR wheels with tires weigh less than one of the old wheels, and those are heavy by today's standards! |

| |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Tue Oct 18, 2016 1:24 am Posted:

Tue Oct 18, 2016 1:24 am |

|

| SEBSPEED wrote: |

I'm fairly convinced the stock wheels and rotors are cast from lead. Why not trash those in favor of lighter items instead?

Both of my CBR wheels with tires weigh less than one of the old wheels, and those are heavy by today's standards! |

Yeah, I know. But it's not a race bike so I'm trying to keep a period correct look. |

_________________

Cary |

|

|

|

n8n8n8

Twinstar

Joined: Dec 07, 2012

Posts: 254

Location: Akron, oh

|

Posted:

Tue Oct 18, 2016 1:51 am Posted:

Tue Oct 18, 2016 1:51 am |

|

I like the swing arm. I have the same one, but made of steel. it also only has one bolt per adjuster. |

_________________

1981 900f |

|

|

|

SteveG

Silver CB900F

Joined: Apr 07, 2006

Posts: 1551

Location: Skaneateles, NY

|

Posted:

Tue Oct 18, 2016 12:20 pm Posted:

Tue Oct 18, 2016 12:20 pm |

|

That is one very, very nice F.

Steve |

_________________

\'79 CB750(810)F, \'81 CB900(985)F, \'82 CB900(Going to be 1100)F, \'82 CBX, \'06 WeeStrom, \'22 CanAm Ryker Rally |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Tue Oct 18, 2016 4:28 pm Posted:

Tue Oct 18, 2016 4:28 pm |

|

Thanks Steve. It's been labor of love. I still have a long way to go to get it where I want it. |

_________________

Cary |

|

|

|

JJam

Red CB1100F

Joined: Nov 08, 2009

Posts: 3821

Location: Sandy OR

|

Posted:

Wed Oct 19, 2016 2:55 pm Posted:

Wed Oct 19, 2016 2:55 pm |

|

Ti axle you say?? How hard is it to get a good finish on that stuff? Did you use a grinder on the lathe?

I haven't tried machining any Ti yet. |

| |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Wed Oct 19, 2016 7:01 pm Posted:

Wed Oct 19, 2016 7:01 pm |

|

I use carbide cutting tools on the lathe and grade 5 titanium finishes really well. No grinding or polishing is required. Here's one of my latest parts; a rear footpeg bushing and washer.

|

_________________

Cary |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Wed Oct 19, 2016 7:03 pm Posted:

Wed Oct 19, 2016 7:03 pm |

|

BTW, it's much easier to work with than stainless. |

_________________

Cary |

|

|

|

JJam

Red CB1100F

Joined: Nov 08, 2009

Posts: 3821

Location: Sandy OR

|

Posted:

Thu Oct 20, 2016 4:15 am Posted:

Thu Oct 20, 2016 4:15 am |

|

Nice. I need to buy some and try it. |

| |

|

|

|

Captain

CB1100F

Joined: Jan 02, 2009

Posts: 2250

Location: New Zealand

|

Posted:

Thu Oct 20, 2016 4:24 am Posted:

Thu Oct 20, 2016 4:24 am |

|

Try drilling a hole in it or even better, tapping it !!!!

Captain |

_________________

The answer is always "more power" always was, always is and always will be. |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Thu Oct 20, 2016 6:01 pm Posted:

Thu Oct 20, 2016 6:01 pm |

|

Yes, drilling a hole can be challenging. I always use coolant to reduce the heat buildup and subsequent work hardening. Tapping is even more challenging. There are titanium specific taps but I was able to tap the axle using a 3 flute HSS tap. |

_________________

Cary |

|

|

|

1100russ

CB1100F

Joined: May 17, 2010

Posts: 2982

Location: williamsburg, ohio

|

Posted:

Thu Oct 20, 2016 7:11 pm Posted:

Thu Oct 20, 2016 7:11 pm |

|

| headless wrote: |

| Yes, drilling a hole can be challenging. I always use coolant to reduce the heat buildup and subsequent work hardening. Tapping is even more challenging. There are titanium specific taps but I was able to tap the axle using a 3 flute HSS tap. |

That is impressive.........  |

_________________

CB1100F The Hot Rod

CB985F The Track Bike

ST1100 Commuter Bike

XR100 Teaching Bike

Ducati 750 SS Track Bike

CB360 Little Honda |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Fri Oct 21, 2016 1:37 am Posted:

Fri Oct 21, 2016 1:37 am |

|

I drilled some safety wire holes today and didn't break the 1/16" drill bit.

|

_________________

Cary |

|

|

|

nlovie

Black CB750F

Joined: May 30, 2015

Posts: 882

Location: United Kingdom

|

Posted:

Fri Oct 21, 2016 10:18 am Posted:

Fri Oct 21, 2016 10:18 am |

|

the re birth of a dying technique - "je ne sais quoi"  |

| |

|

|

|

JJam

Red CB1100F

Joined: Nov 08, 2009

Posts: 3821

Location: Sandy OR

|

Posted:

Fri Oct 21, 2016 7:16 pm Posted:

Fri Oct 21, 2016 7:16 pm |

|

| headless wrote: |

I drilled some safety wire holes today and didn't break the 1/16" drill bit.

|

Cary are you making the bolts also or are they from ProBolt? |

| |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Fri Oct 21, 2016 7:57 pm Posted:

Fri Oct 21, 2016 7:57 pm |

|

I'm not making them. Some are from proBolt, but most are sourced elsewhere. I buy a lot off eBay from China or the UK and some are from TitanClassics.com. |

_________________

Cary |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Wed Nov 09, 2016 10:21 pm Posted:

Wed Nov 09, 2016 10:21 pm |

|

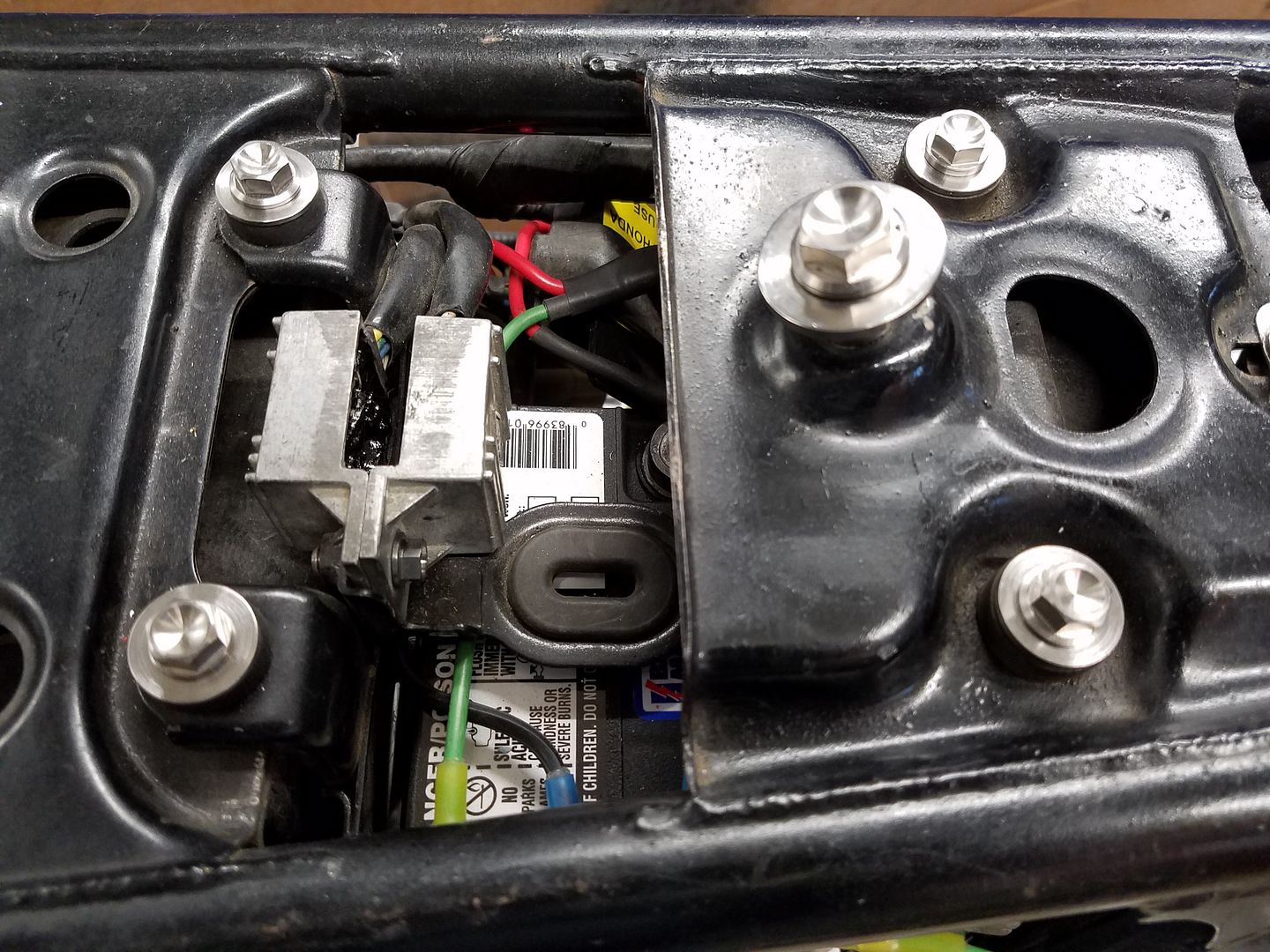

I added titanium tank hold down hardware today.

|

_________________

Cary |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Sun Nov 20, 2016 9:58 pm Posted:

Sun Nov 20, 2016 9:58 pm |

|

More titanium bling.

|

_________________

Cary |

|

|

|

nlovie

Black CB750F

Joined: May 30, 2015

Posts: 882

Location: United Kingdom

|

Posted:

Mon Nov 21, 2016 8:50 am Posted:

Mon Nov 21, 2016 8:50 am |

|

nice - had a go at tapping 12mm grade 6 using a cheap tungsten alloy split die - great! - nicer thread than the same die on carbon steel or SS but the ti has its own technique

you need a good clamp for the stock - ideally a 3 or 4 jaw - it seems i'm partially pressure forming the thread - kinda like a rolled thread

1st - grind a nice lead in taper to match that of the die to give an easy thread start

2nd - I use a cutting paste + light oil lub

3rd - x 3 pass's with the die - hence a split die so you can adjust the diameter of cut

4th - its tough work! - I need to use a 12" die holder for leverage - hence also the need for a good clamp - it kinda goes like - wind up the elastic spring in the ti then you get a shear - back off half turn and repeat easing fwd, take your time and feel for any heat build up ( it feels like it wants to bind up and weld together versus cut so avoid heat

but - end result is good and the die is still sharp ( i've done x 4 with the same die)

5th - I found the thread high point was a larger diameter than the stock I started with ( part to do with the pressure forming) so I take the peak off with a diamond sharping file - just a few thou, if I don't do this - its sharp enough to cut the nut thread |

| |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Mon Nov 21, 2016 5:39 pm Posted:

Mon Nov 21, 2016 5:39 pm |

|

Nice work. I'll have to give that a try. |

_________________

Cary |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Thu Nov 24, 2016 3:04 am Posted:

Thu Nov 24, 2016 3:04 am |

|

I made a front wheel spacer today and saved a whopping 17 grams of unsprung weight.

The front axle is now on the drawing board. |

_________________

Cary |

|

|

|

DonR

CB1100F

Joined: Feb 17, 2009

Posts: 2110

Location: Oz

|

Posted:

Thu Nov 24, 2016 3:09 am Posted:

Thu Nov 24, 2016 3:09 am |

|

| headless wrote: |

| I made a front wheel spacer today and saved a whopping 17 grams of unsprung weight. |

Aluminium ones would be 40% lighter still....just sayin' |

| |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Thu Nov 24, 2016 3:16 am Posted:

Thu Nov 24, 2016 3:16 am |

|

good point.  |

_________________

Cary |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Sat Dec 17, 2016 7:56 pm Posted:

Sat Dec 17, 2016 7:56 pm |

|

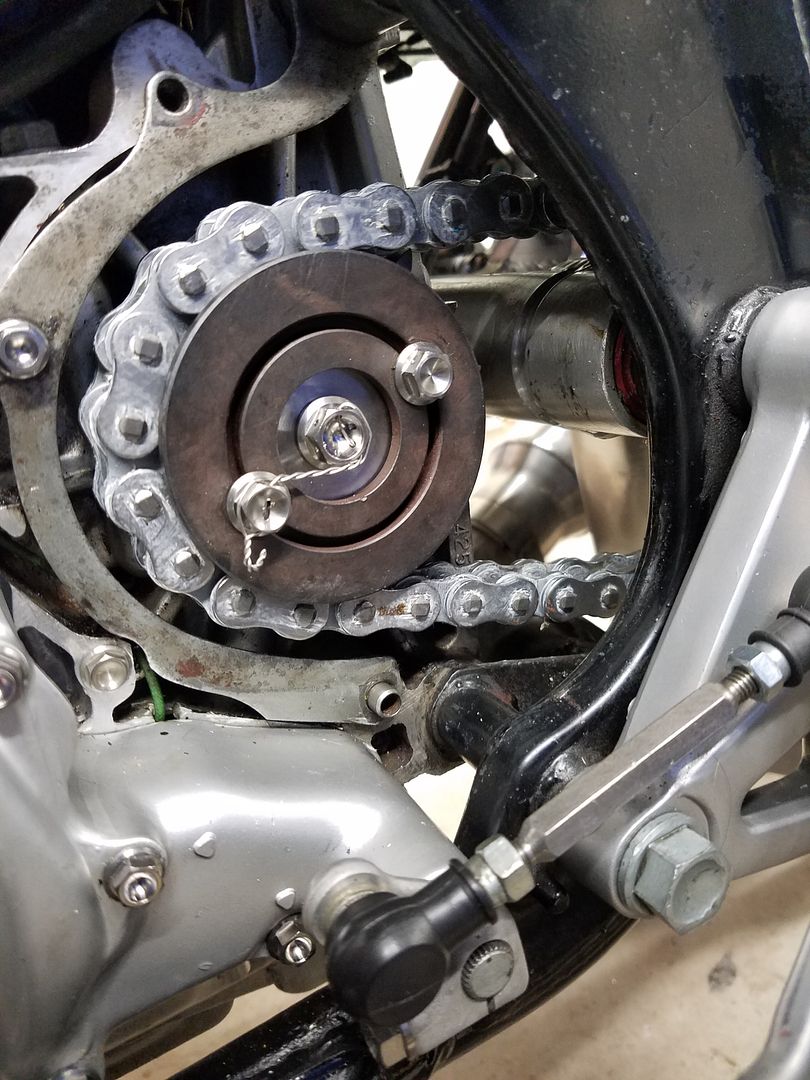

I just added titanium sprocket bolts and washer.

|

_________________

Cary |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Sun Dec 25, 2016 1:30 am Posted:

Sun Dec 25, 2016 1:30 am |

|

I purchased a lathe milling attachment and made a front axle.

|

_________________

Cary |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Tue Dec 27, 2016 7:29 pm Posted:

Tue Dec 27, 2016 7:29 pm |

|

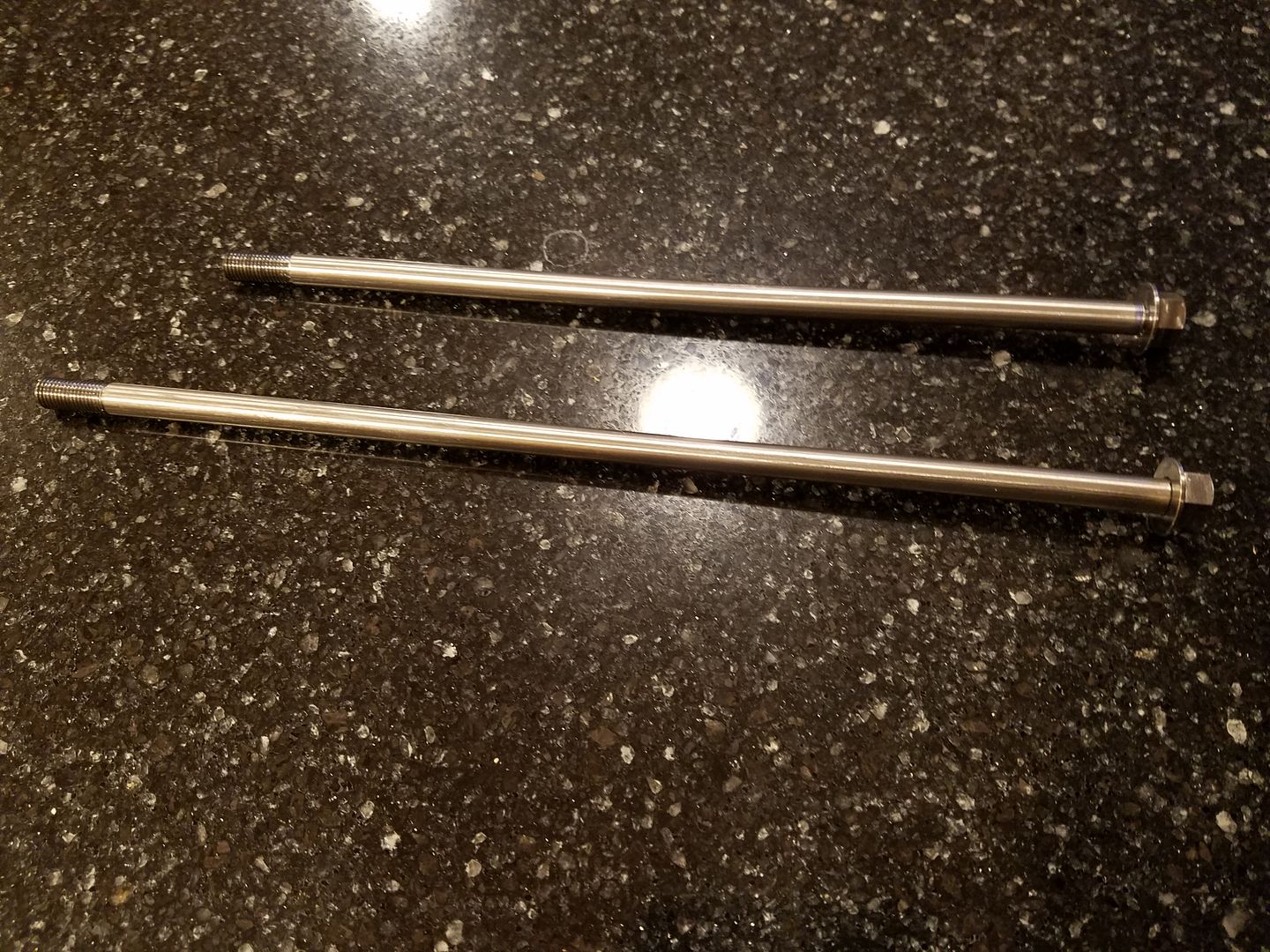

I made 2 (M10x284 & M10x330) engine mounting bolts. Just a few more items and I'll be done.

|

_________________

Cary |

|

|

|

JJam

Red CB1100F

Joined: Nov 08, 2009

Posts: 3821

Location: Sandy OR

|

Posted:

Wed Dec 28, 2016 3:08 am Posted:

Wed Dec 28, 2016 3:08 am |

|

Except for mine. I'd like the motor mount bolts and axles and a swingafrm pivot bolt to my specs. Just let me know Cary and I'll send the info.

Looks NICE BTW. |

| |

|

|

|

grump

Red CB1100F

Joined: Jul 13, 2004

Posts: 5627

Location: Grass Valley,California, USA

|

Posted:

Wed Dec 28, 2016 2:28 pm Posted:

Wed Dec 28, 2016 2:28 pm |

|

OK I'm outta my depth here but would like to learn even at this late date. Often my queries don't get answered because they are so ignorant.

How can TI be both easy to machine and difficult to drill? |

| |

|

|

|

headless

CB1100F

Joined: Sep 03, 2008

Posts: 2045

Location: Eugene, OR

|

Posted:

Wed Dec 28, 2016 4:33 pm Posted:

Wed Dec 28, 2016 4:33 pm |

|

Grade 5 titanium comes in it's annealed state so it is fairly easy to machine if you use single point tools and keep the feed and speed down. It is twice as elastic as steel so it will tend to deflect when cut. It also doesn't transfer heat as readily so heat concentrates at the cutting surface and can get quite hot. Unless the heat is controlled by coolant the subsequent work hardening can result in dull tools & chipped or deformed surfaces. Unless you have thru drill coolant then drilling is a slow and difficult process. I peck drill to keep the chip load down and flood with coolant using a squeeze bottle. |

_________________

Cary |

|

|

|

|

|